2026/02/05

2026/01/27

2025/12/22

Amid the accelerating energy transition, solar power has emerged as a leading renewable energy source. As a core component of PV systems, the inverter not only performs power conversion but also determines the overall energy efficiency of PV systems with its Maximum Power Point Tracking (MPPT) functionality.

The value of MPPT lies in the nonlinear relationship between PV module output power and voltage. Variations in irradiance or temperature can cause the operating point to drift away from the maximum power point. By adjusting the operating state in real time, inverters ensure that PV panels consistently operate at the maximum power point. This real-time dynamic adjustment defines the essence of MPPT. In other words, MPPT is the key mechanism for inverters to enhance power generation efficiency of systems.

According to the International Energy Agency (IEA), newly installed PV capacity around the globe reached 530GW in 2024, with China contributing over 50%. As PV deployment accelerates, inverter architectures continue to evolve, and the number of MPPT channels, their configuration methods, and hardware implementation have become critical variables in system design. Starting from a look at the energy flow path, this article will delve into the working principle of MPPT, its technical implementation pathways, and corresponding solutions across three mainstream inverter architectures.

01 Where Does MPPT Fit in the PV System Energy Path?

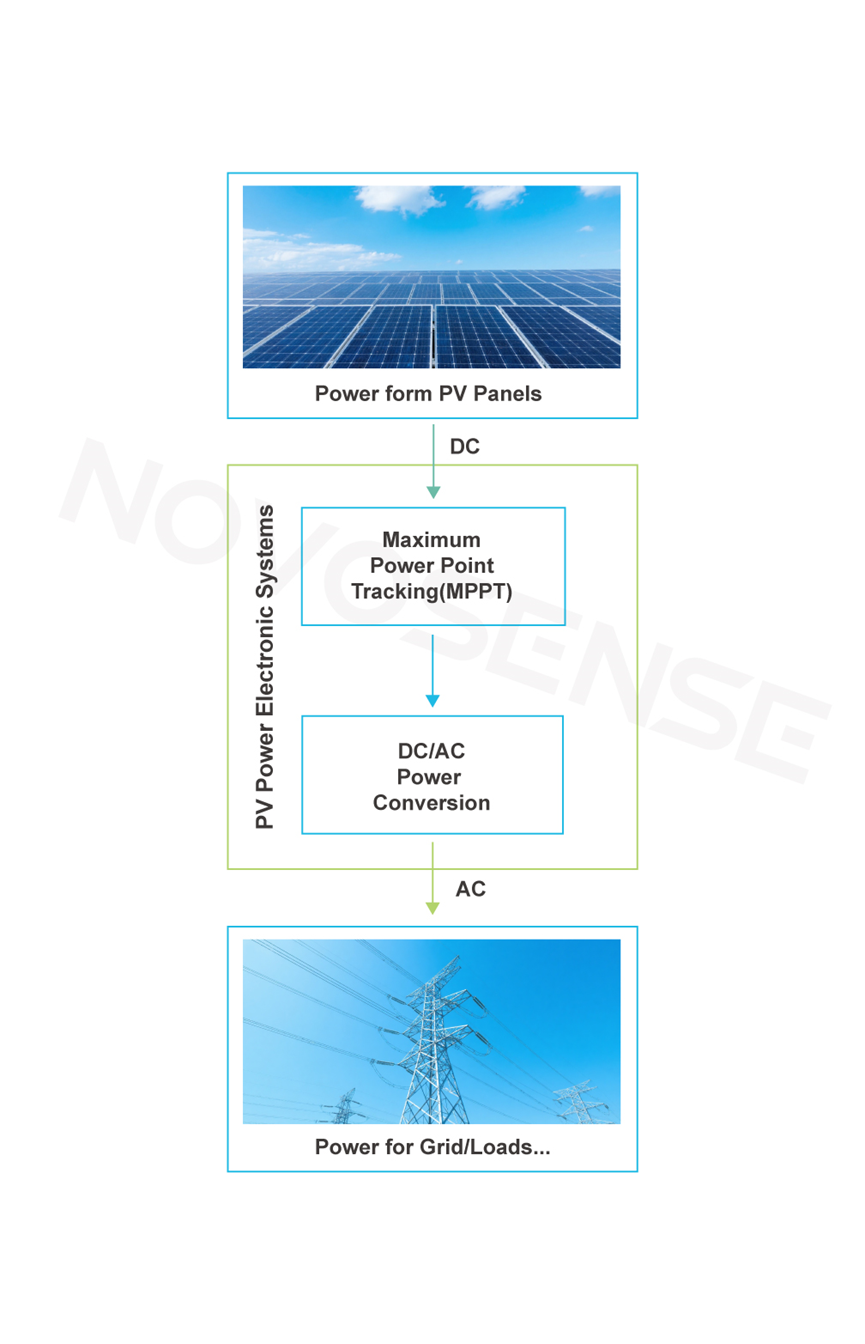

From the perspective of energy flow, a PV power generation system consists of three key components: PV modules, power electronics system, and the grid or load. PV modules are at the input end. Under sunlight, PV modules convert solar energy into electrical energy through the photovoltaic effect and output direct current (DC) power.. The grid/load serves as the output end of a PV system. Since most power consumption, transmission, and distribution rely on alternating current (AC) grids, a dedicated power electronics system is required to convert the DC power generated by PV modules into AC power for grid integration or residential use.

Basic Structure of a PV Power Generation System

The power electronics system in a PV system performs two fundamental functions: DC-to-AC power conversion, and MPPT control, a unique and critical functionality of PV inverters.

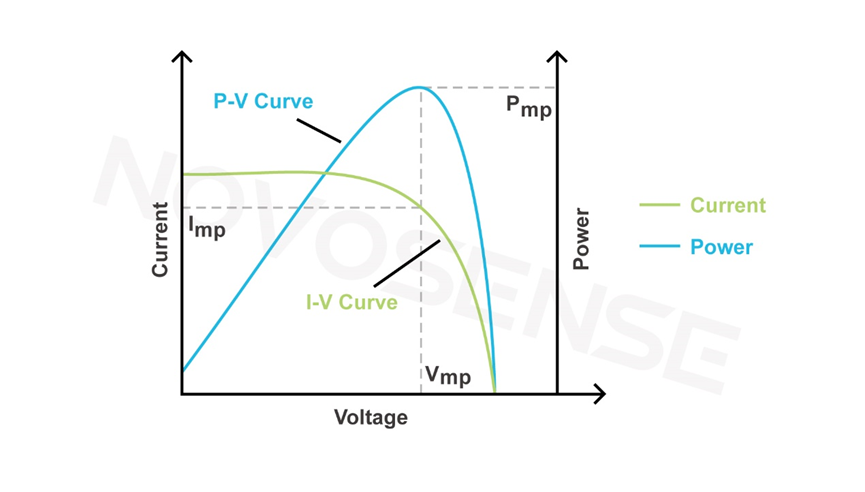

MPPT is essential because the output power of PV modules is a nonlinear function of voltage and has a maximum power point. From the generation side, users naturally expect more energy from PV systems under the same sunlight conditions, which requires maintaining the operating state of PV modules at the maximum power point.

Schematic Diagram of Maximum Power Point

From both physical and control perspectives, achieving this typically requires a DC-DC converter and an MPPT control algorithm.

In summary, PV systems collect solar energy through PV modules and convert it into DC, which is then converted into AC by the power electronics system that provides MPPT and DC-AC conversion capabilities. The output AC power is finally delivered to the grid or load. This constitutes the most basic operating mechanism of a PV system.

02 How MPPT Works from the Perspective of Power and Control Chains?

The implementation of MPPT functionality relies on the precise, stable, and efficient operation of the entire power and information chain.

The MPPT function operates through three interlinked stages: sensing, computation, and driving. Accurate voltage and current sensing provides real-time data; the control unit computes the optimal operating point using MPPT algorithms; and the driver circuitry executes the control commands through precise gate operation.

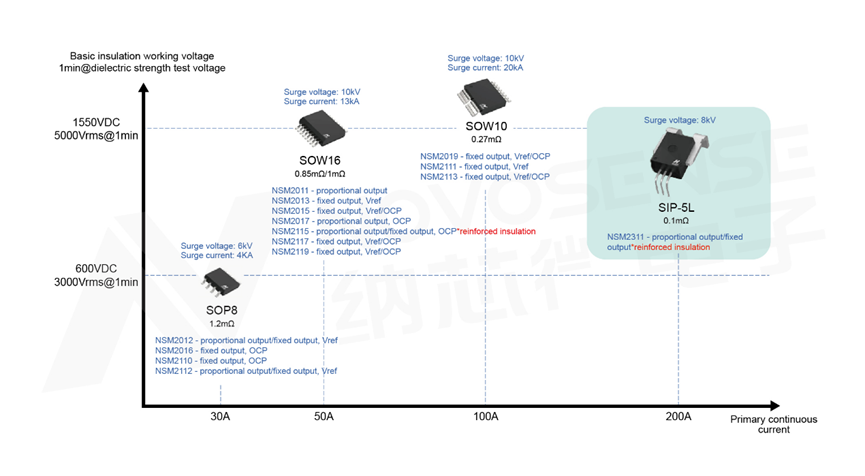

First, "sensing" requires accurate power measurement, which in turn requires both voltage and current data. Voltage, due to its inherent physical properties, is relatively easy to acquire and process. In contrast, accurate current measurement is more challenging, making current sensors crucial in this process. NOVOSENSE NSM201x series Hall-effect current sensors, based on the Hall effect, support isolated current measurements within ±65A, and output linear voltage signals. Featuring excellent reliability and accuracy, they enable the control system to precisely capture power states.

![]()

NSM201x Package Diagram

Second, "computation" requires a high-performance real-time control system, typically implemented using MCUs or DSPs. The controller executes the internal MPPT algorithm to determine the operating point while performing real-time control – converting the conceptual "operating point" instruction into high-frequency, high-precision PWM signals to precisely regulate the operating state of power devices.

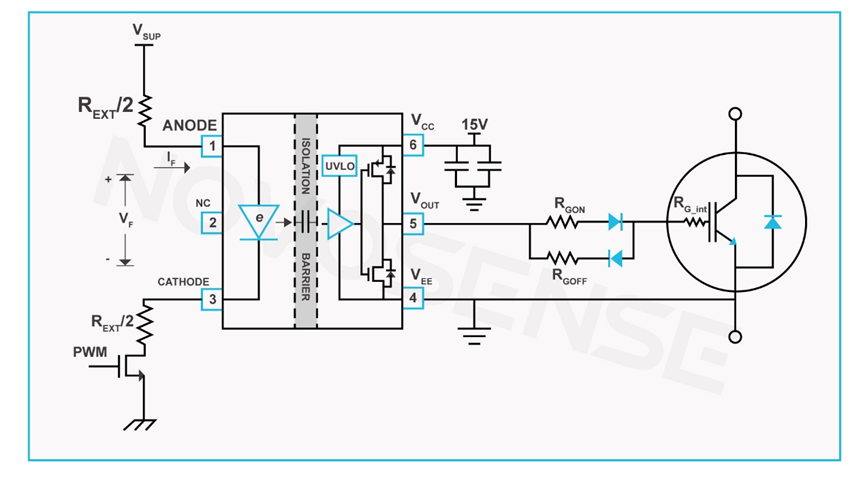

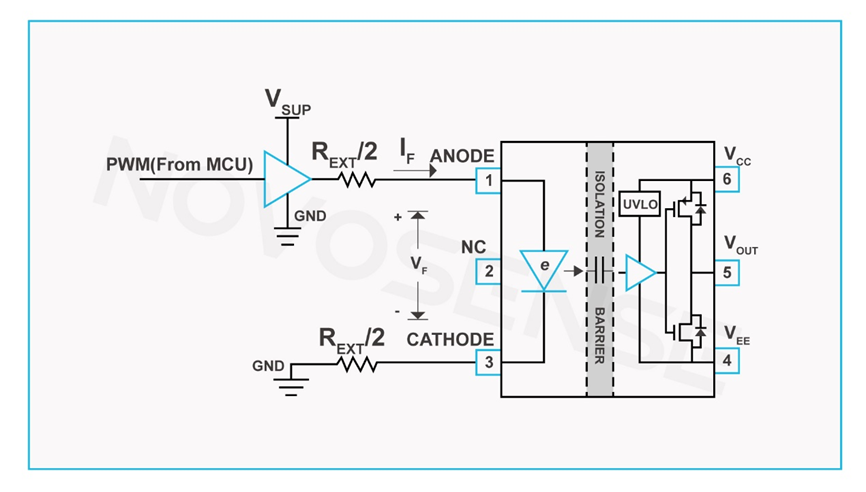

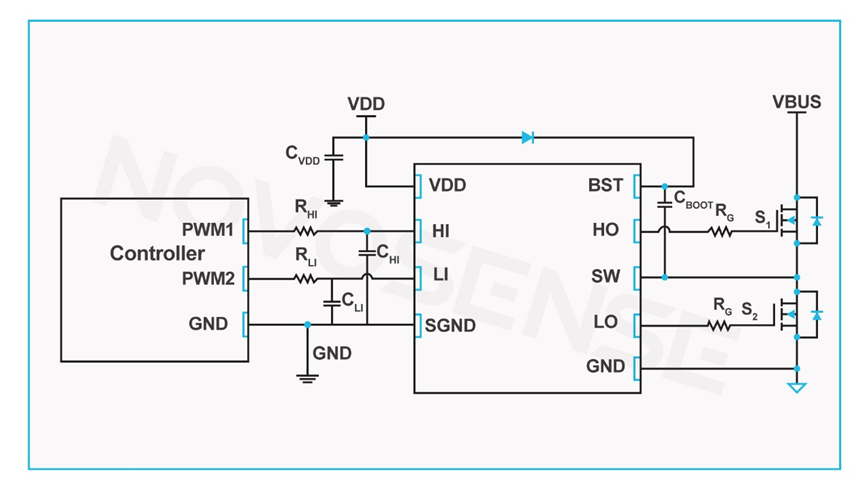

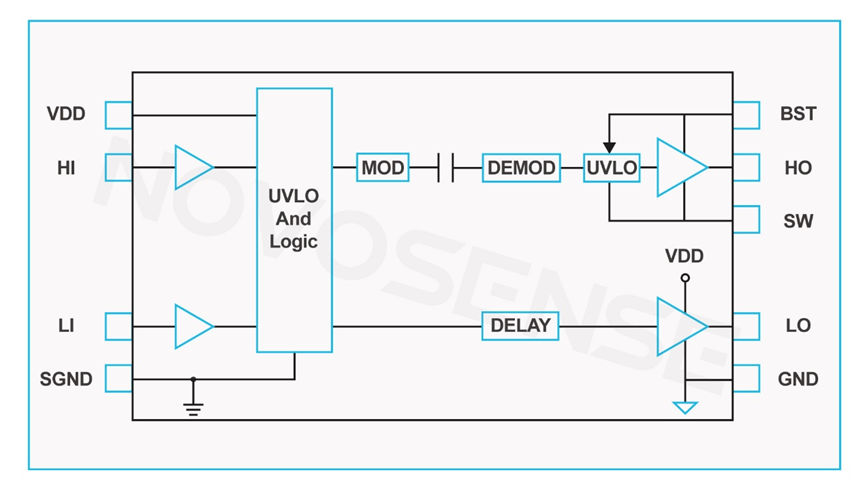

Finally, "driving" depends on robust and reliable gate drivers and power devices to ensure accurate execution of MCU commands. The NSI6801/x series current-input isolated single-channel gate drivers from NOVOSENSE are widely adopted in PV inverters, and represent reference-grade driver solutions. Featuring the dual-capacitor reinforced isolation architecture, these drivers are pin-to-pin compatible with optocoupler-based drivers while providing superior isolation performance. In addition, NOVOSENSE’s proprietary AdaptiveOOK® encoding technology enables the NSI6801/x series to achieve up to 200 kV/μs CMTI. These exceptional features ensure system safety, stability, and efficiency.

Typical Application Circuits for MOSFET Driver and Buffer Driver

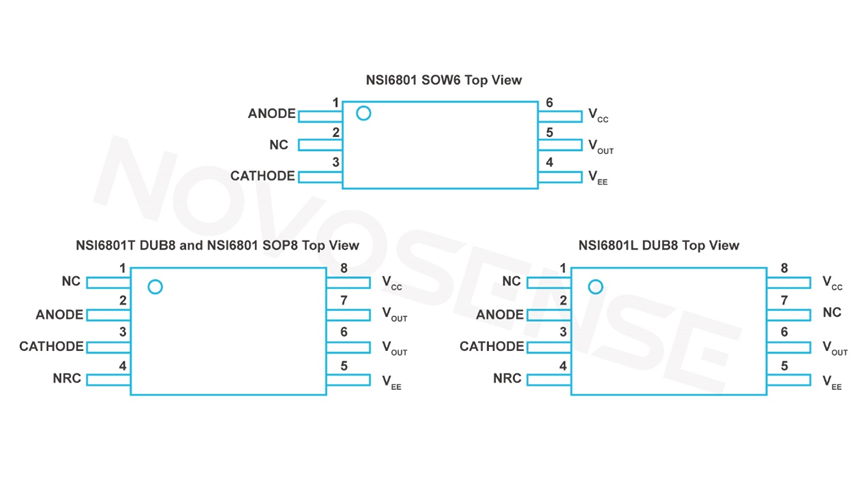

NSI6801 Package Types and Pin Definitions

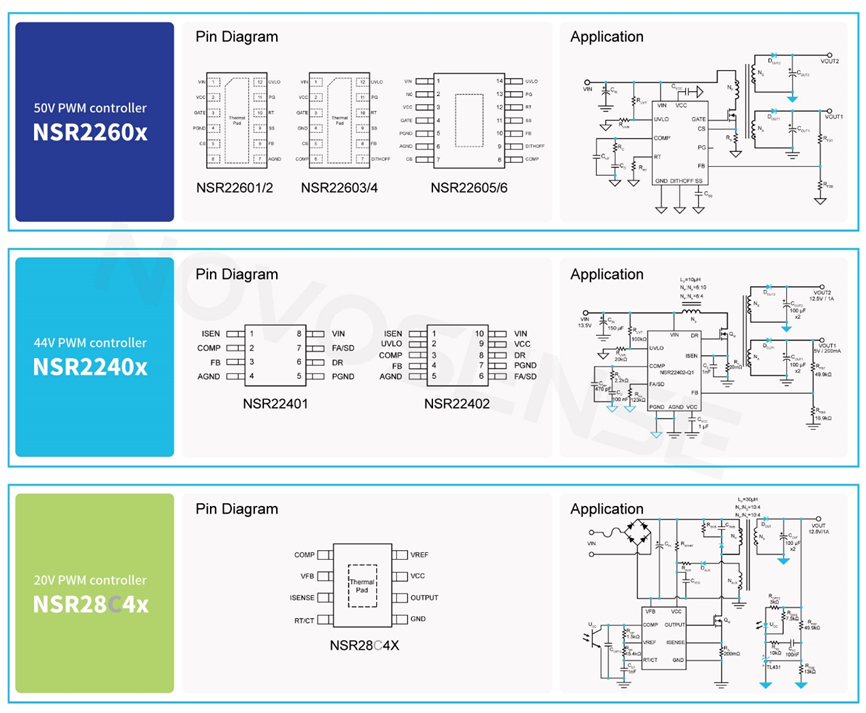

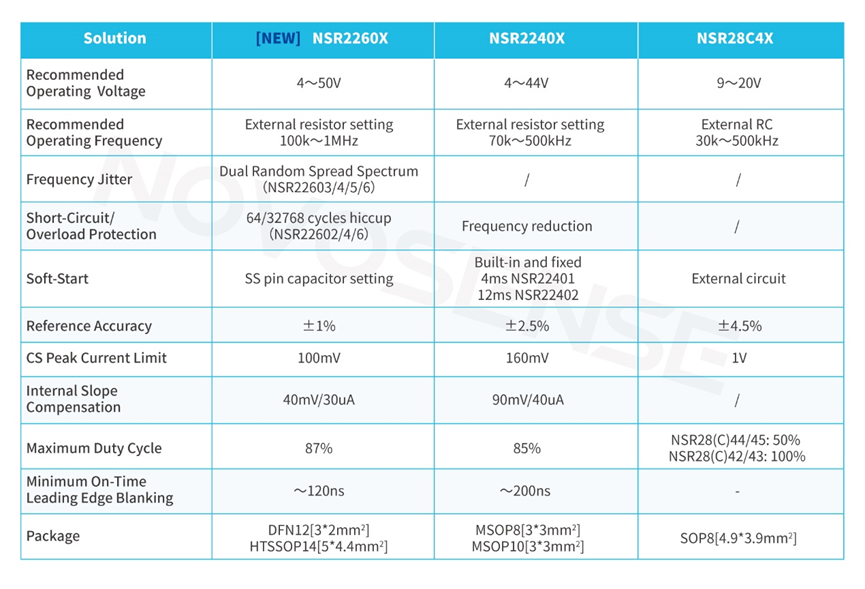

Furthermore, stable and reliable power management ICs are equally critical. NOVOSENSE offers a wide range of high-performance power solutions, answering needs from main controller supply to standby interface power. Among them, the NSR2260x, NSR2240x, NSR28C4x, and NSR284x series current-mode PWM controllers are suitable for flyback topologies, delivering outstanding stability and efficiency to support stable and high-performance sampling, control, and driving functions.

NOVOSENSE PWM Controller Overview and Product Selection Guide

03 How do MPPT count and configuration define the “efficiency ceiling” across three inverter types?

In existing PV systems, the power electronics system is typically integrated into the inverter. From a hardware structure perspective, most PV inverters consist of two stages: DC-DC and DC-AC. The DC-DC stage is primarily used for MPPT control, while the DC-AC stage is used for AC output ("inversion").

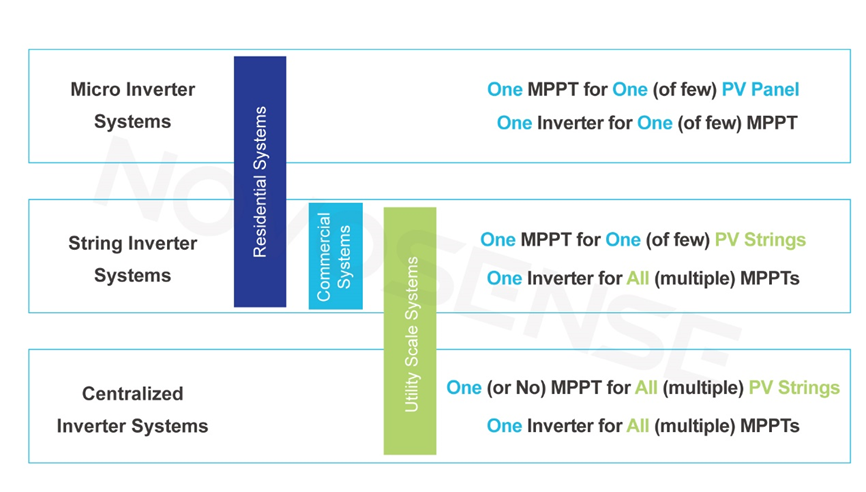

There are three main types of PV inverters: microinverters, string inverters, and centralized inverters. They differ significantly in terms of MPPT allocation, inverter stages, and configuration.

PV Inverter Classification and MPPT Configurations

Microinverters perform MPPT at the level of individual PV modules. Each PV module is paired with its own MPPT function and inverter stage, forming a 1:1:1 relationship of module : MPPT : inverter. While hardware costs are relatively high due to per-module MPPT, this fine-grained control ensures that every module operates at its optimal point. As a result, microinverters can maximize power output, enhance system revenue, improve safety through module-level monitoring, and reduce maintenance costs.

NSD1624 high-voltage half-bridge driver from NOVOSENSE is a benchmark solution for driving power devices on the PV side in microinverters. The NSD1624 employs mature and reliable capacitive isolation technology for high-voltage half-bridge driving, offering stronger dv/dt immunity and negative voltage oscillation tolerance compared to traditional HVIC processes. With 4A/6A drive current and low propagation delays, it is ideal for high-frequency switching applications. Aligning with microinverters’ trend toward miniaturization and higher switching frequency, the NSD1624 helps achieve higher efficiency and power density.

NSD1624’s Functional Block Diagram and Simplified Application Circuit

String inverters do not target individual PV modules, but group multiple PV modules into a string (PV string), with each string typically assigned one MPPT channel. A single inverter stage may serve multiple MPPT-controlled strings. Compared to microinverters, string inverters provide less granular control but lower hardware cost.

Centralized inverters adopt a "coarser" approach, aggregating dozens, hundreds, or even thousands of PV modules, with only one or no MPPT channel, paired with a single inverter stage. Although centralized inverters offer less precise control, they have the lowest hardware cost.

As inverter scale increases from micro to string to centralized architectures, the control granularity of each PV module decreases accordingly. Different inverter types are suitable for distinct applications: residential systems typically favor microinverters and string inverters; commercial and industrial systems mostly employ string inverters; utility-scale power stations may select either string or centralized PV inverters depending on system design.

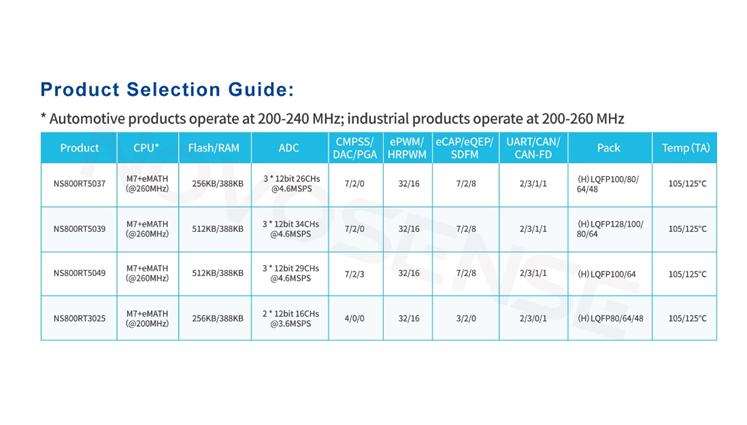

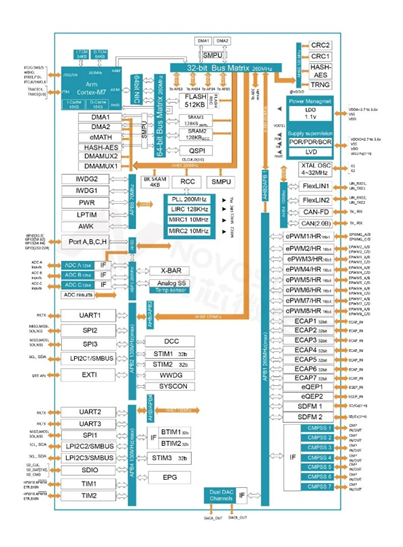

Although different inverter types vary in control channels and power levels, MCUs generally serve as the central system controller. The NSSine™ real-time control MCUs from NOVOSENSE – NS800RT5039, NS800RT5049, and NS800RT3025 – offer efficient real-time control capabilities and rich peripheral integration. They enable engineers to achieve nanosecond-level PWM precision for PV and energy-storage inverters, enhancing overall system accuracy and efficiency.

NSSine™ Real-Time Control MCU Selection Guide and Functional Block Diagram

Precise and stable MPPT control ensures efficient and reliable operation of PV systems. NOVOSENSE, focusing on application-driven product development, has launched well-received products across MPPT implementation, including the NSM201x current sensor and the NSI6801x isolated single-channel gate driver, further expanding with the high-performance NSSine™ real-time control MCUs and NSD1624 high-voltage half-bridge driver for PV-side power devices. Together, these products address the core needs of all inverter architectures, helping engineers design PV systems that are both efficient and reliable.For the products mentioned above, sample requests can be made at www.novosns.com. For further inquiries, please contact sales@novosns.com.