2026/02/05

2026/01/27

2025/12/22

2026/02/05

In industrial control, product competitiveness is no longer defined by a single performance metric. Instead, it is increasingly evaluated through a system-level lens—balancing efficiency, precision, reliability, and intelligence. While cost optimization and miniaturization remain fundamental, energy efficiency, microsecond-level response, high-reliability operation, and network connectivity are becoming key enablers across PLCs, motor drives, servo systems, and robotics.

Driven by application innovation, NOVOSENSE delivers a full-chain semiconductor portfolio spanning signal sensing and processing, interface, power management, driver IC, ISO sampling, power stage and MCU. These solutions are designed to address core system challenges in real-time performance, precision, energy efficiency, and long-term reliability. The following sections illustrate how application-defined chip design supports the continuous evolution of industrial control systems.

PLC & Signal Acquisition: High-Integration Interfaces for Diverse System Requirements

PLCs serve as centralized signal-processing hubs within industrial control systems, interfacing with field sensors, actuators, and control networks across analog, digital, and communication domains. As system scale and functional integration increase, PLC architectures demand higher interface density, stronger isolation capability, and consistent signal-processing performance.

NOVOSENSE supports PLC applications through:

Coverage of both analog and digital control domains to accommodate diverse signal acquisition requirements

Digital isolation solutions with higher integration and speed compared with traditional optocouplers

High-integration digital output devices adaptable to multiple load types

For compact PLC deployments, NOVOSENSE offers the capacitive-isolation-based NSI860x digital input isolator family, including the 4-channel NSI8604 and 8-channel NSI8608. These devices integrate digital input and output functionality, support −60 V to +60 V digital input signals, maintain compatibility with optocoupler current-input interfaces, require no field-side power supply, and provide isolated digital outputs—enabling highly stable and space-efficient system design.

NSI8604: SSOP16 package (left) and NSI8608: SSOP20 package (right)

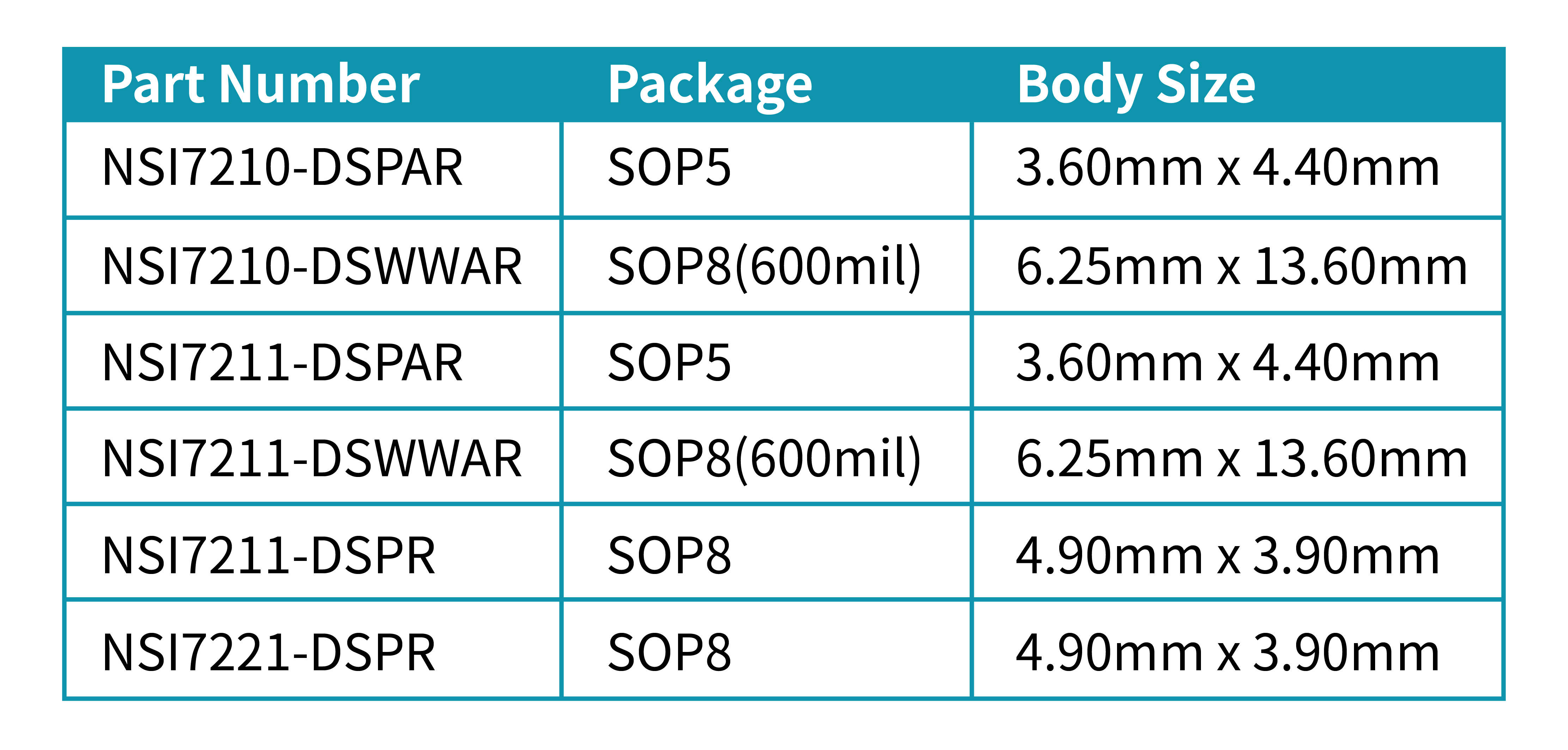

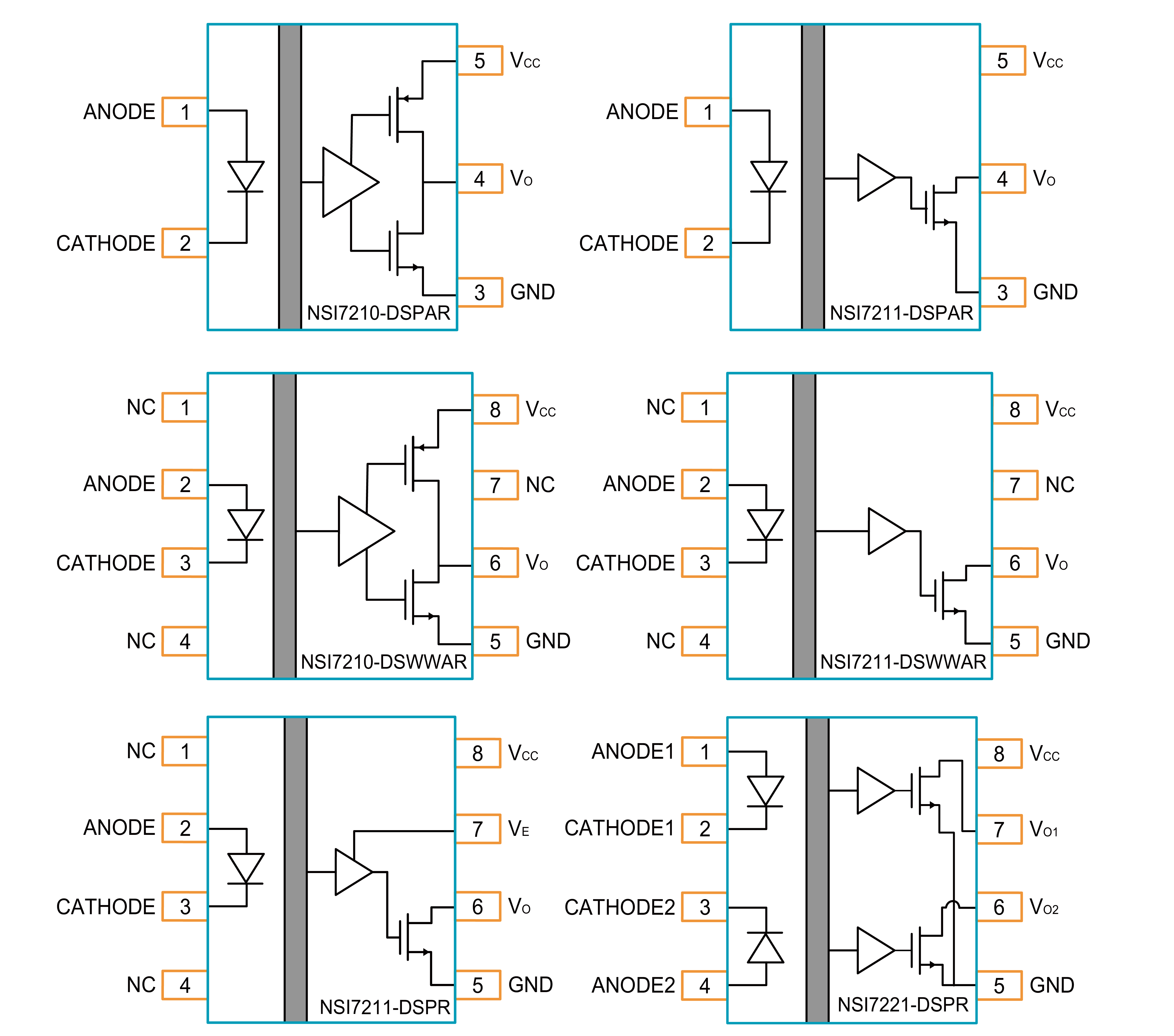

NSI72xx selection guide and functional block diagram

For millisecond- to microsecond-level data processing and response requirements, the NS800RT7377D real-time control MCU provides dual Cortex®-M7 cores operating at 400 MHz, extensive peripheral integration, and built-in protection features. Equipped with 40 PWM channels—including 16 high-resolution 124 ps HRPWM channels and 24 enhanced EPWM channels—it enables ultra-precise power control and improved system stability for high-precision industrial applications.

Motor Control: Device Adaptation and System-Level Coordination

Industrial motor control encompasses diverse applications—from stepper motors to inverters and servo systems—each requiring distinct control strategies and performance characteristics. NOVOSENSE provides semiconductor solutions tailored to these varied scenarios, supporting flexible and application-specific system design.

Stepper Motors: Dedicated Drivers for Smooth, Low-Noise, Reliable Operation

Stepper motors convert MCU-generated electrical pulses into angular or linear motion and can operate under open-loop control, delivering incremental displacement per pulse. Compared with conventional DC control architectures, they offer cost advantages and are widely used in CNC equipment, printers, and industrial positioning systems.

System performance—including motion smoothness, acoustic noise, and reliability under abnormal conditions—largely depends on the driver’s current regulation, microstepping capability, and diagnostic functions.

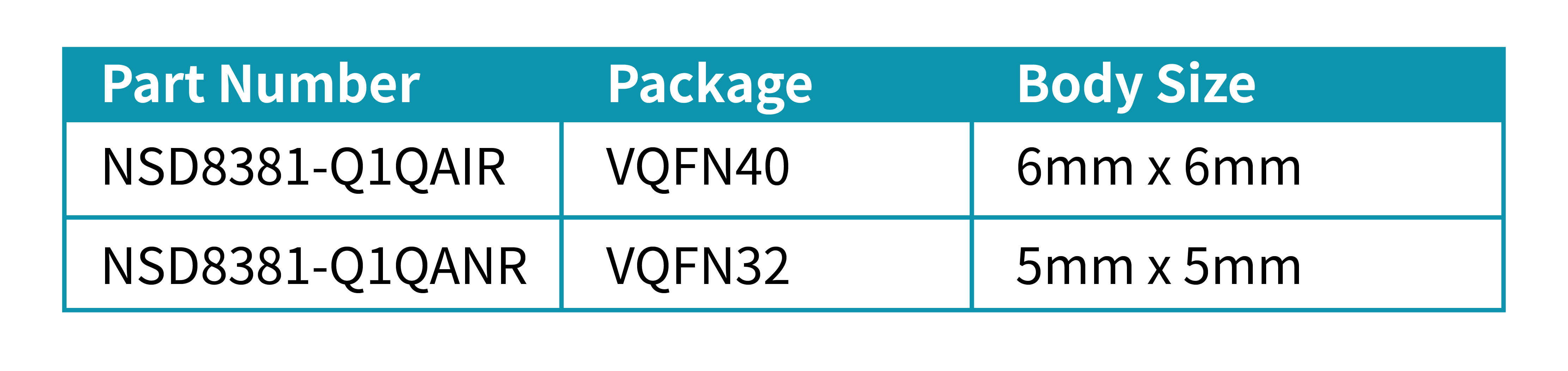

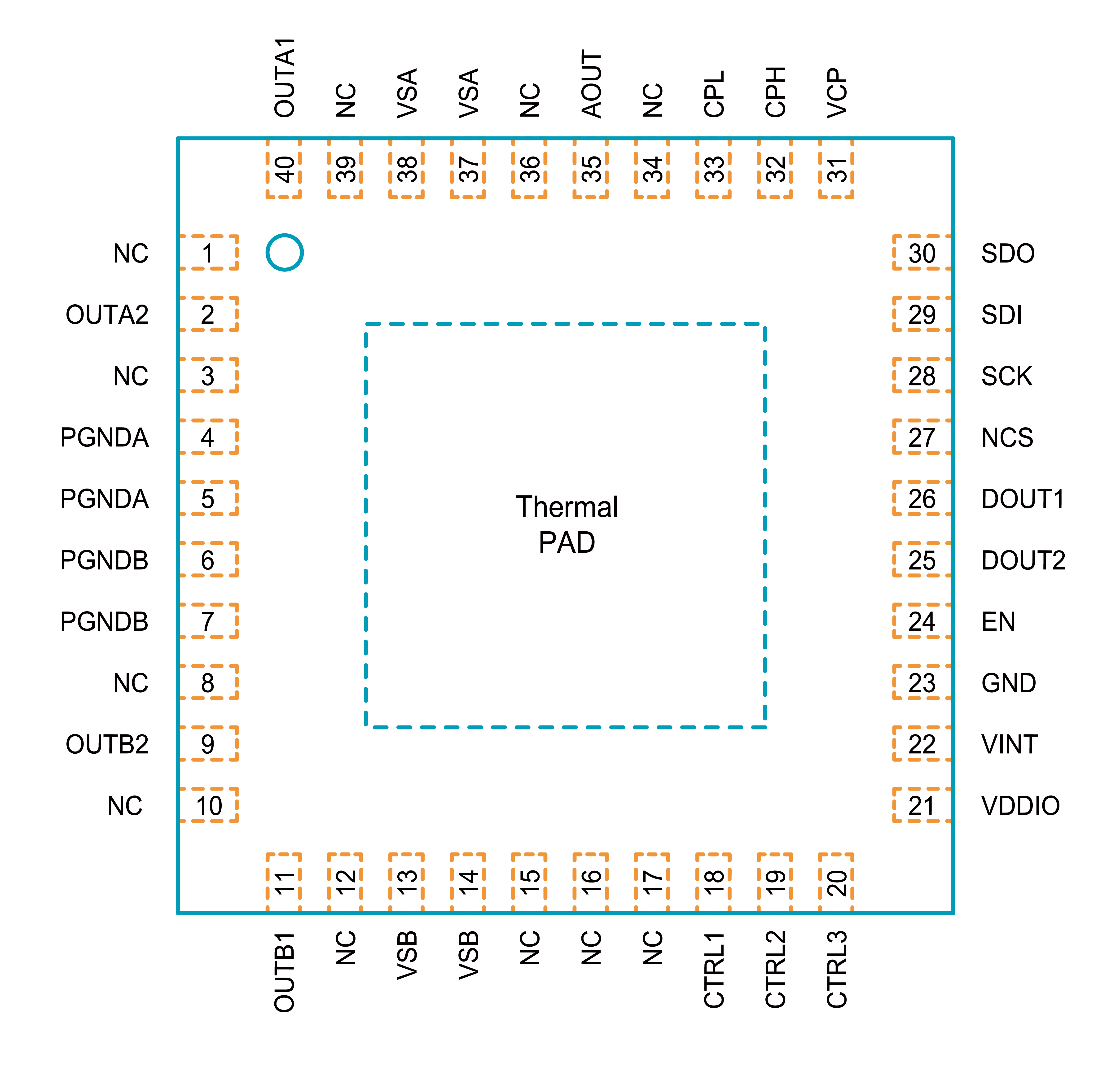

The NSD8381 dual-phase bipolar stepper motor driver supports full-scale current up to 1.35 A and integrates current-chopping regulation, up to 1/32 microstepping, and selectable decay modes. These features enable smooth motion control and robust operation across applications such as automotive headlamp positioning (ADB/AFS), HUD adjustment motors, thermal-management valves, and BDC motor systems.

Inverters: Isolation Gate Drivers Enhancing Consistency and Lifetime

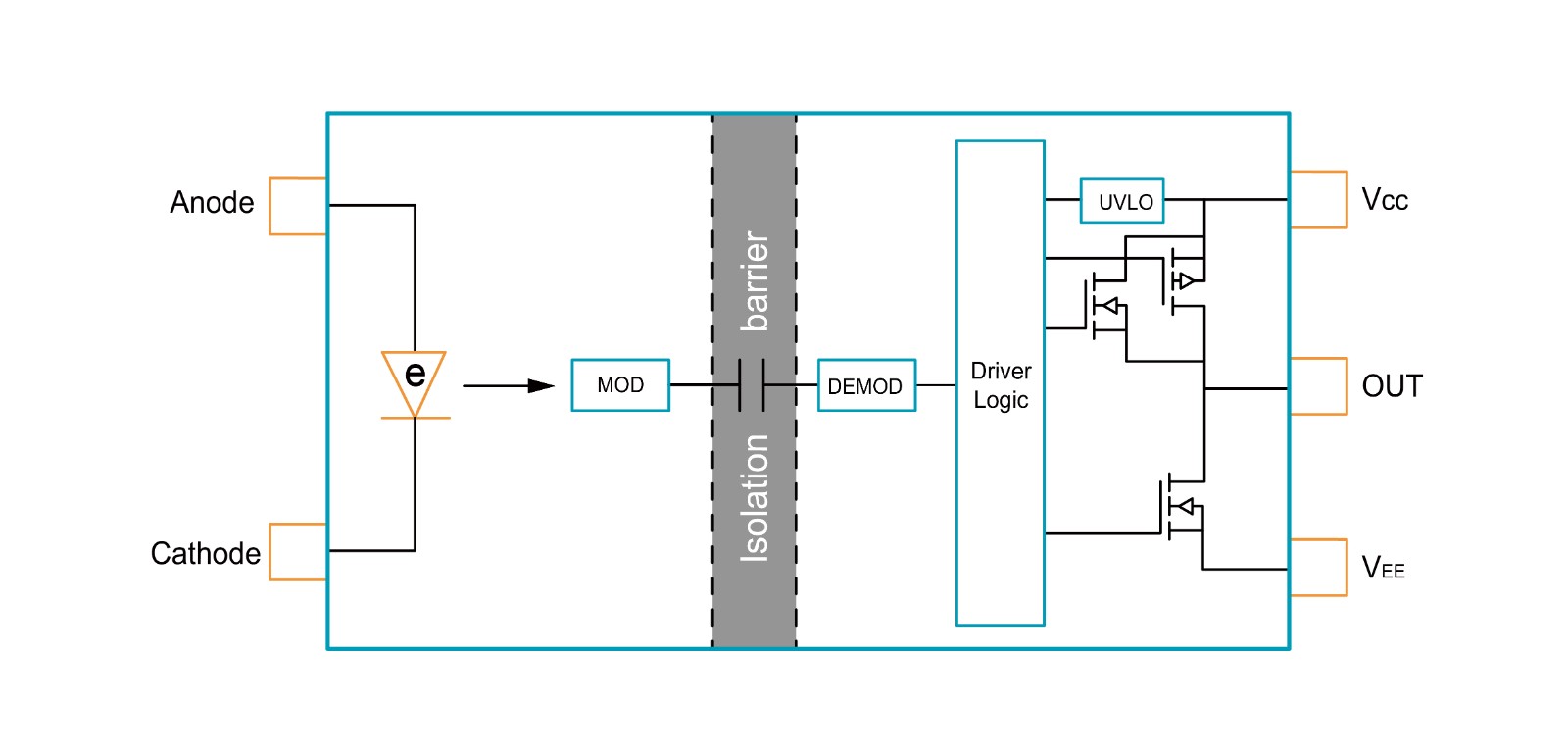

NOVOSENSE provides current-driven isolated gate drivers including the NSI6801 family, along with the enhanced NSI6801Ex and NSI6801xC series, offering performance improvements and cost advantages. These devices are pin-compatible with optocoupler-based gate drivers and enable direct replacement in inverter designs.

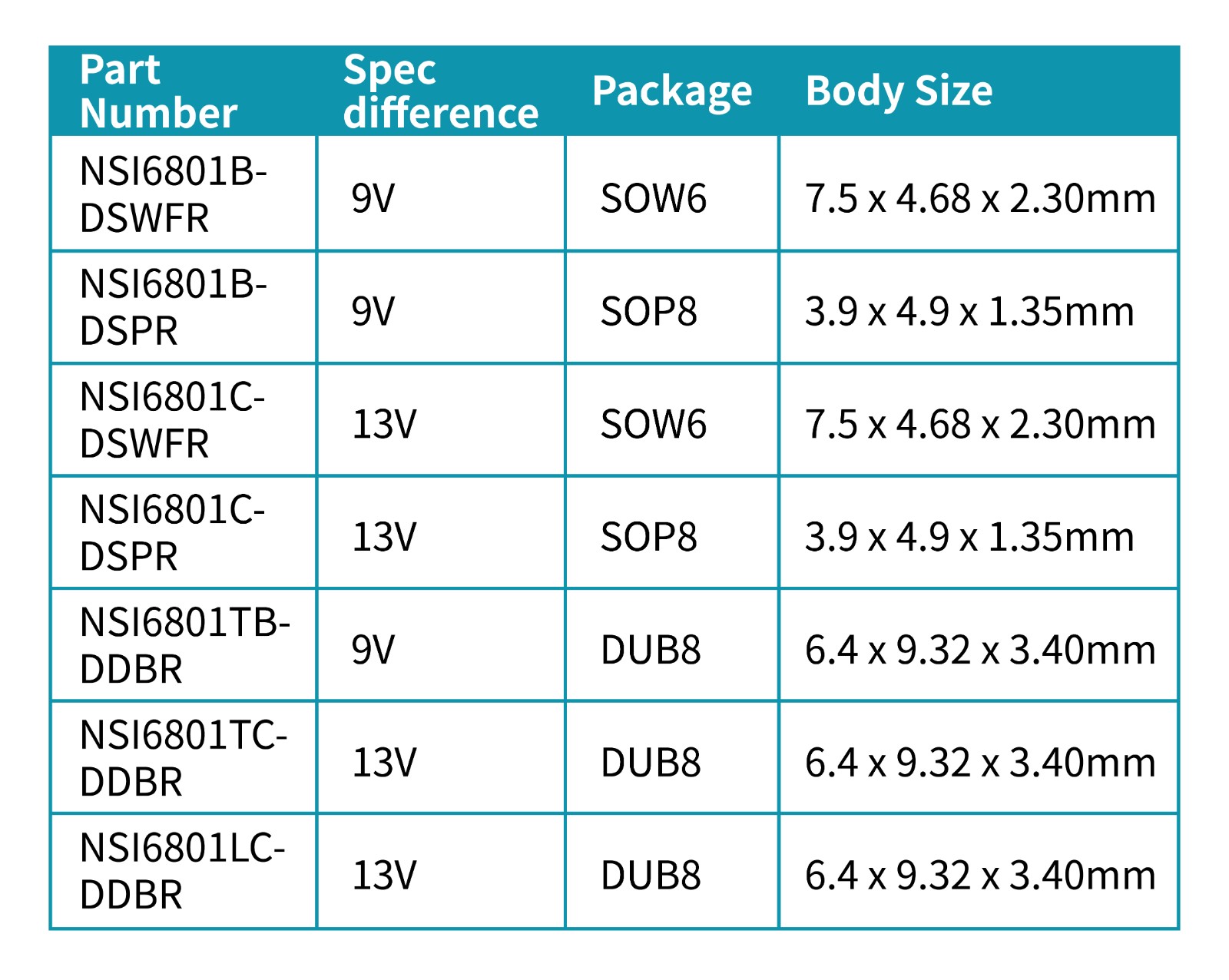

NSI6801 current-driven isolated gate driver: functional block diagram and selection guide

![]()

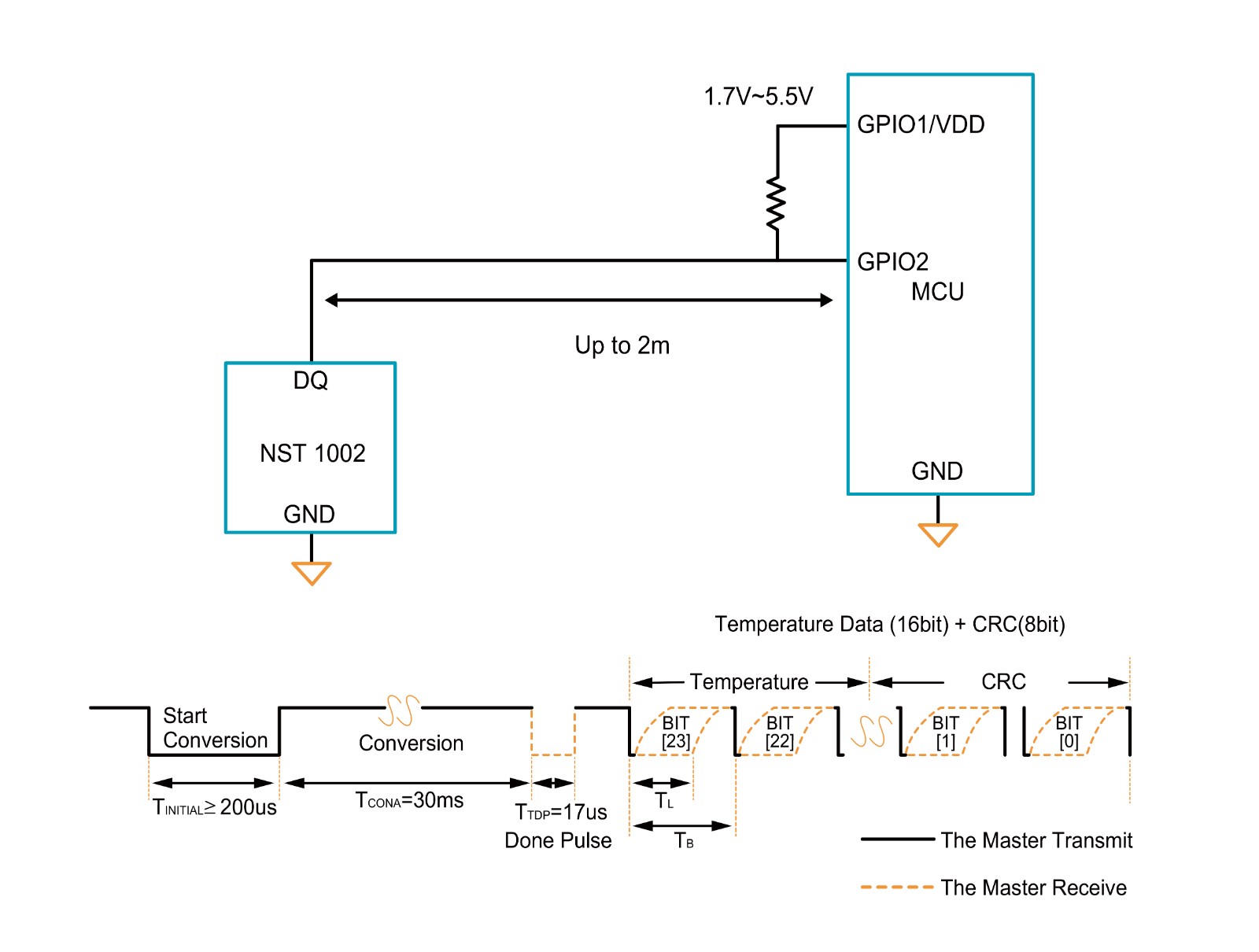

NST1002 temperature sensor: functional block diagram and selection guide

Servo motors operate under closed-loop control, relying on encoders to provide real-time speed and position feedback. Encoder accuracy, stability, and environmental robustness directly determine system performance. Magnetic encoders, known for their reliability and resistance to environmental interference, are increasingly preferred in industrial servo applications.

Traditional magnetic encoder architectures typically combine AMR sensing elements, signal-processing circuits, and high-performance MCUs or discrete multi-channel ADCs, resulting in complex and costly implementations.

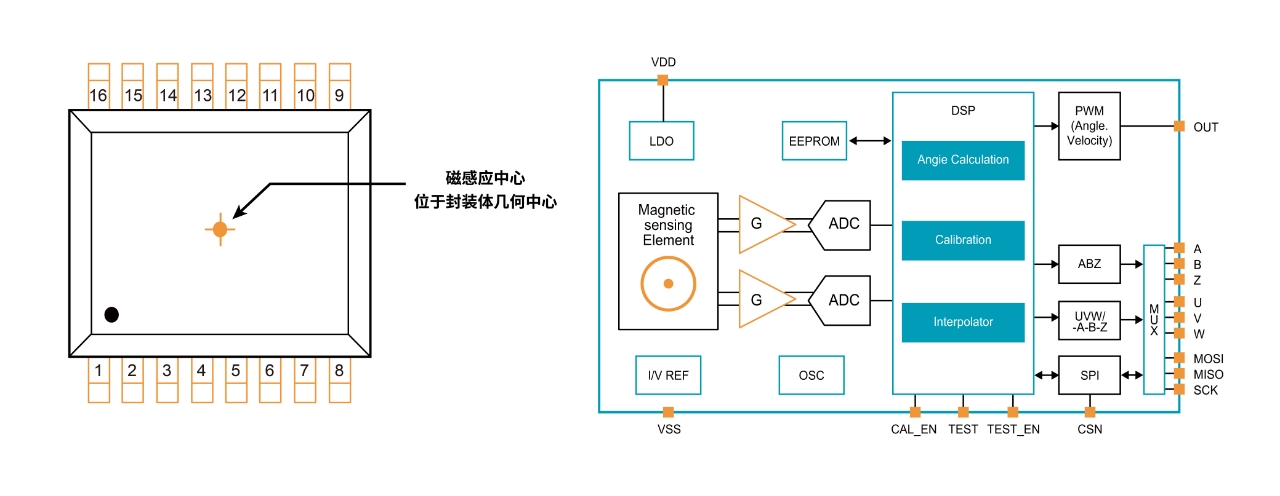

NOVOSENSE’s MT6835 integrates angle sensing, DSP-based processing, and direct angle output in a single chip, simplifying system architecture. The next-generation MT6826S high-speed, high-precision angle encoder, based on advanced AMR technology, supports client-side calibration to compensate for magnet imperfections and installation offsets, significantly improving INL performance.

MT683: TSSOP-16 package overview and functional block diagram

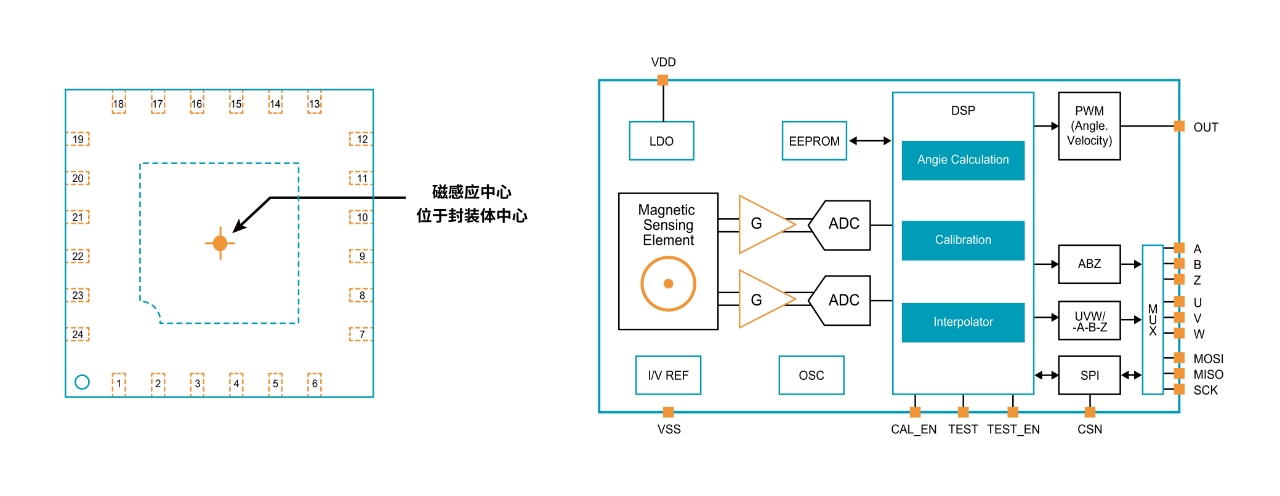

MT6826S: QFN 4×4-24L package overview and functional block diagram

In high-power inverter and servo environments, power devices operate under high voltage and current for extended periods. Driver reliability and protection capability are therefore critical. NOVOSENSE offers low-side drivers with integrated DESAT protection, including NSD1015MT/T, as well as intelligent isolated single-channel drivers such as NSI68515 compatible with optocoupler pinouts. These solutions support both isolated and non-isolated implementations, improving reliability while reducing system cost and PCB area.

Intelligent single-channel non-isolated gate driver NSD1015T (left), NSD1015MT (right): functional block diagram

Dedicated processor SoC NSUC1610: functional block diagram

For motor shaft position detection, magnetic encoders are gradually replacing optical encoders due to their vibration tolerance and environmental robustness. Compared with traditional multi-component magnetic encoder architectures, the MT6835 integrates angle calculation and signal processing, significantly simplifying system design. Combined with NS300K214 and Hall devices, it forms a complete magnetic encoder solution that reduces system cost while maintaining performance—ideal for space- and cost-sensitive robotic applications.

Driving the Evolution of Industrial Control Systems

Industrial control technologies are advancing toward higher energy efficiency, greater precision, enhanced reliability, and intelligent operation—making highly integrated semiconductors central to system architecture.Across PLCs, motor control, inverters, magnetic encoders, and humanoid robotics, semiconductor solutions continue to evolve toward higher integration, faster response, and stronger system adaptability—supporting the next generation of industrial automation.For more information on the NOVOSENSE products mentioned in this article, please visit www.novosns.com to request samples or contact us at sales@novosns.com.